What is the Thing in Internet of Things

The Thing in ‘Internet of Things’ could be an asset, a person or a key process parameter, that a Production Manager would want to measure and improve……..

Production Line Enabling

As a Production Manager, you may have one or more of these Problems

- Improving Process Efficiency by reducing TAKT (Process Turnaround Time)

- Pallet Tracking in-house and at vendor locations

- Asset Tracking in-house and at vendor locations

- Vehicle Tracking

- Forklift Tracking and Optimization

- Casual Labor Tracking

What do I do as a Production Manager?

- Identify Key Pain Areas and Process Improvisation Opportunities

- Workout Tangible outcomes e.g. TAKT to reduce by 20%, Yield per day to increase by 10% in one month and so on

- Select a small business case/process area

- Work out all the challenges, Inputs, and outputs to the system

- Seek and Solution Provider and work out candidates for digitalization

- Identify Automation Opportunities using IoT

- Defined Dashboards and key metrics for predictable gains and Hyper Decisions

- Roll out POC plan and execute

- Observe outcomes and then scale to bigger process applications

A solution to Business Problems

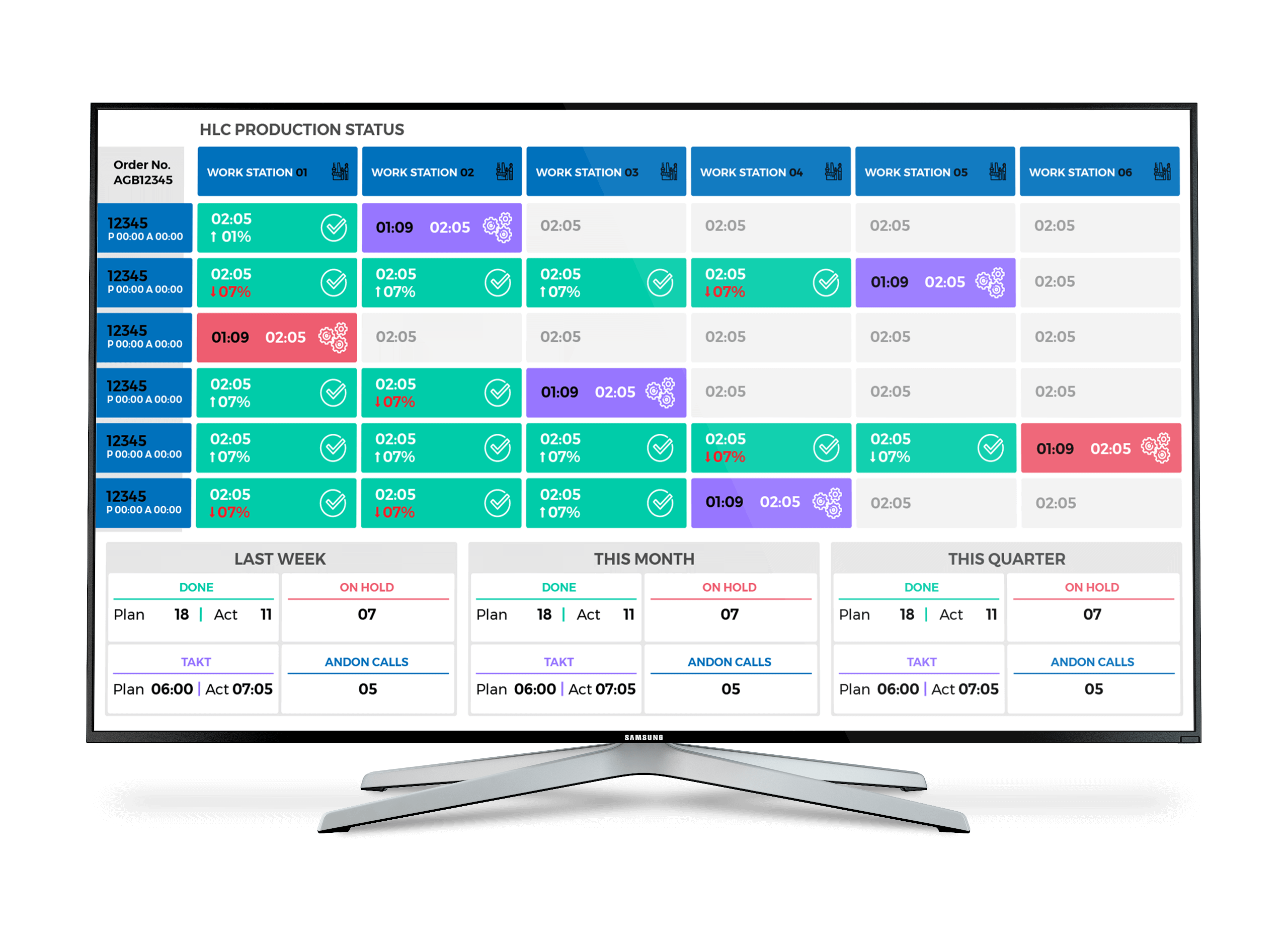

Improving Process Efficiency by reducing TAKT (Process Turnaround Time)

Pain Area

- Too much time gets wasted using manual processes for material requests from stores

- Time wasted in holding production line for want of material from vendor

- Production Delays due to a technical issue on assembly lines and delayed resolution

Solution Approach

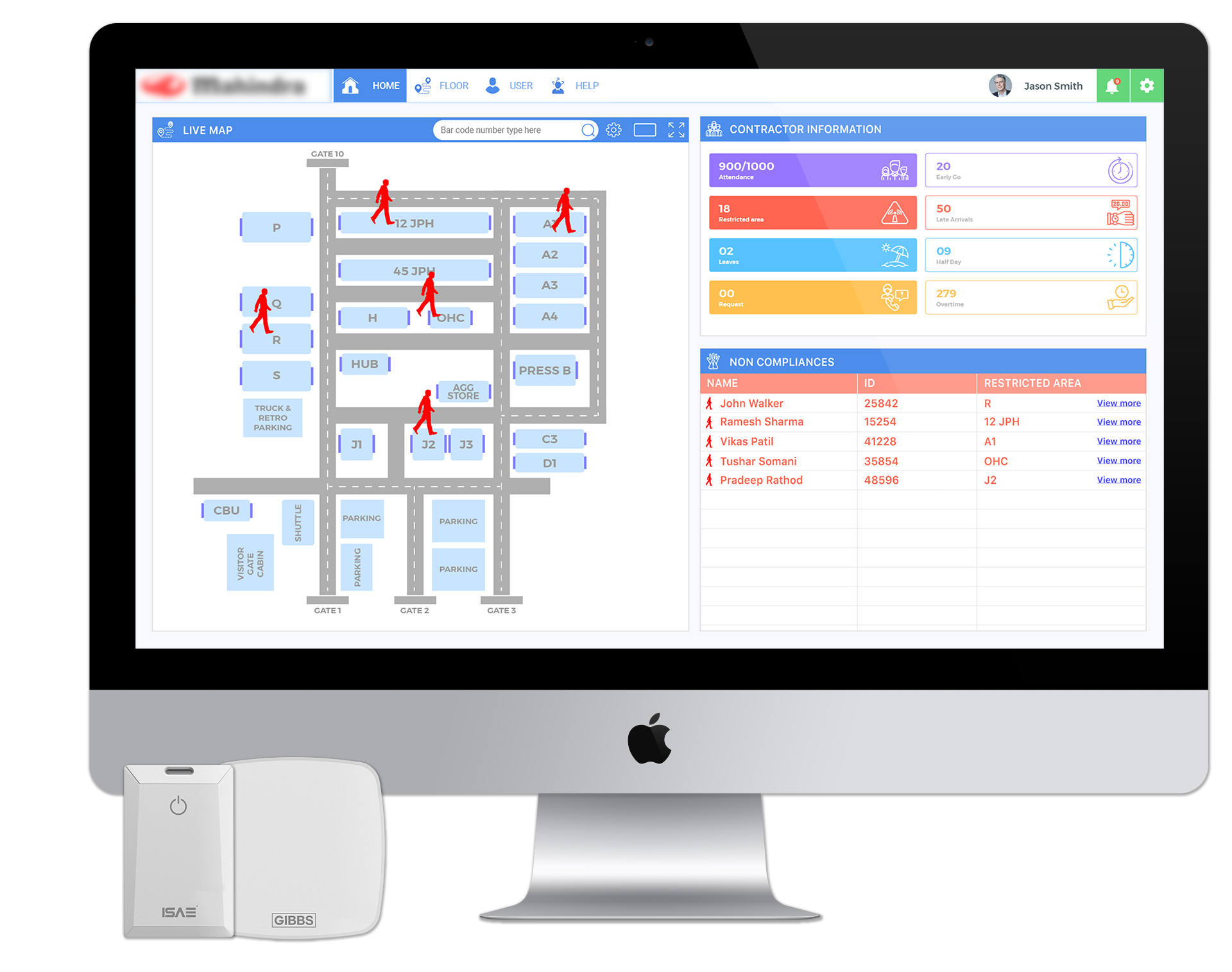

A heterogeneous ISAE (Intelligent Systems Around Everything) Framework based on IoT that connects Pallets, Production Jobs, ANDON Calls, People and Materials to give:

- Real-time production status of a production line on a huge TV screen (As seen above)

- The TV screen depicts the following and can be used for hyper-decision making based on real-time data

- In Progress work stations with lapsed and planned process time (purple color blocks)

- Material or Assistance calls (color red), These are called warehouse kanban or ANDON calls

- Normal operations (color green)

- Inferences in numbers for Week, Month and Quarter as seen on the screen for predictive analysis and planning

Business Benefits

- Up to 30% Improved TAKT resulting in ROI and savings

- 10% to 30%Capacity enhancement resulting in better yield

- Customer Delight due to timely and quality deliverable

Pallet Tracking in-house and at vendor locations

Pain Area

- Pallets at various locations and vendors not available in time or have been inefficiently used

- This causes production delays or damage to products due to wrong pallets

- Revenue losses due to lost pallets, unaccounted for pallets, and subsequently new pallet manufacturing when already pallets are at the vendor location

Solution Approach

- Enabling smart pallets with the use of BLE Tags and BLE Gateways.

- Putting the information on the Web using Real-Time Location System and ISAE framework

- Putting the Gateways in Trucks to track Pallets in Transit and estimated time to arrive

- Realtime dashboard on Laptops and TV screens for hyper decision making

Business Benefits

- Save 100% of revenue lost in misuse of pallets by Vendors

- Accurate location of pallets helps plan delivery and saves TAKT by 20% or more

- The cost of pallet manufacturing can be reduced by up to 30%

- ROI can be realized within 2 months of implementation

Detailed Solution available on Warehouse Pallet Tracking

Asset Tracking in-house and at vendor locations

Pain Area

- Assets at various locations in-house and at vendor shops

- These include Dies, Jigs, and Fixtures

- Finding the location of assets during a health audit is a major pain area and impacts audit timelines and data relevance

- Finding the location and tracking of assets on demand becomes a bottleneck in a manual process system

Solution Approach

- Onboard all assets on the system using BLE Tags and Gateways devices

- Put the information on the Web using Real-Time Location System and ISAE framework

- On-demand audits and health checks using custom apps

- Real-time dashboard on Asset Age, Health, and Location details

- Analytics for decision making

- Digitalization of asset movement and tracking

Business Benefits

- Save 100% of revenue lost in misuse of assets by vendors

- Accurate location of assets helps ensures securing stakeholder’s interest

- 70% cost reduction in audits due to automation

- ROI can be realized within 6 months of implementation

Vehicle Tracking

Pain Areas

- Tracking of Vehicles in Yard and big areas is a manual process and takes hours to search

- Tracking and Scheduling Supplier vehicles is a great challenge

- Vehicles in indoor locations and time at each location are unaccounted for and manually reported introducing efficiency and delay in dispatch

Solution Approach

- Asset tags go on sun visors of vehicles

- BLE Relays are placed at locations that need to be tracked at the micro level

- BLE gateways cover a wider range and transmit signals received from Relays to IoT servers using WiFi

- Onboarding and Mapping against Vehicle Identification Number are done using a mobile app

- Once on the system Vehicles are seen on a virtual floor and can be tracked in real-time

- Real-time dashboard on dwell time and location inference available for management decisions in real-time synthesis

Business Benefits

- Reduction in GATE TAKT for supplier vehicles 20% or more

- Production of automobiles and their delivery are 100% Predictable for automobile industries resulting in customer delight

- Hyper Decision making using real-time dashboards

- Ready for Future Capacity Planning based on historical data

Forklift Tracking and Optimizing

Pain Area

- Not knowing how many forklifts are really needed in production increases the holding cost of forklifts

- Path optimizations where dozens of forklifts are used are very important to generate savings

Solution Approach

- BLE-based asset tags with accelerometers go on the forklifts

- BLE relays are placed in the pathway at a reasonable distance for a range

- BLE Gateways are placed at intermediate locations –

- A web app with a floor map for real-time location tracking is made available to users

- The web has a default dashboard with a basic analysis on forklift movement and inferences

- An application server has the data and application code

- IoT server is hosted on QuicSolv’s cloud or local data center for Forklift location data from gateways and sending back information to the application server

Business Benefits

Based on industry-standard practices and past experience of experts in the area of cost optimization we could think of the following value to the business.

- Reducing number of forklifts – based on Industry analysis we have seen at least 10% to 15% fleet can be reduced after data analysis of actual usage

- Substantial Savings – Based on real-life applications we have achieved as high as 15% Savings within two months of implementation.

Casual Labor Tracking (Dynamic Production Planning)

Pain Areas

- Contractors or in-time labor is a boon but it is very difficult to mange their productivity

- Tracking them on the job is very difficult as they are not on the main HR channel

- Billing/invoicing and security are big challenges when it comes to casual labor

Solution Approach

- BLE based ID cards assigned to Casual Labors

- Gateways go in Pick-up Bus and Real-time Locations on shop floors

- Before one is logging into the gate the real-time picture of the strength of the team is known well in advance

- This help replanning and dynamic changes to scheduled deliverable

Business Benefits

- 20% time saved in re-planning

- 30% cost saving in production losses

- 100% ROI in 6 months

Click here to know more on Dynamic Planning and Control

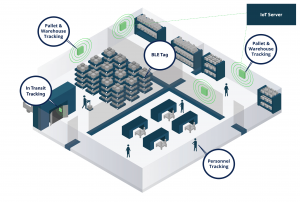

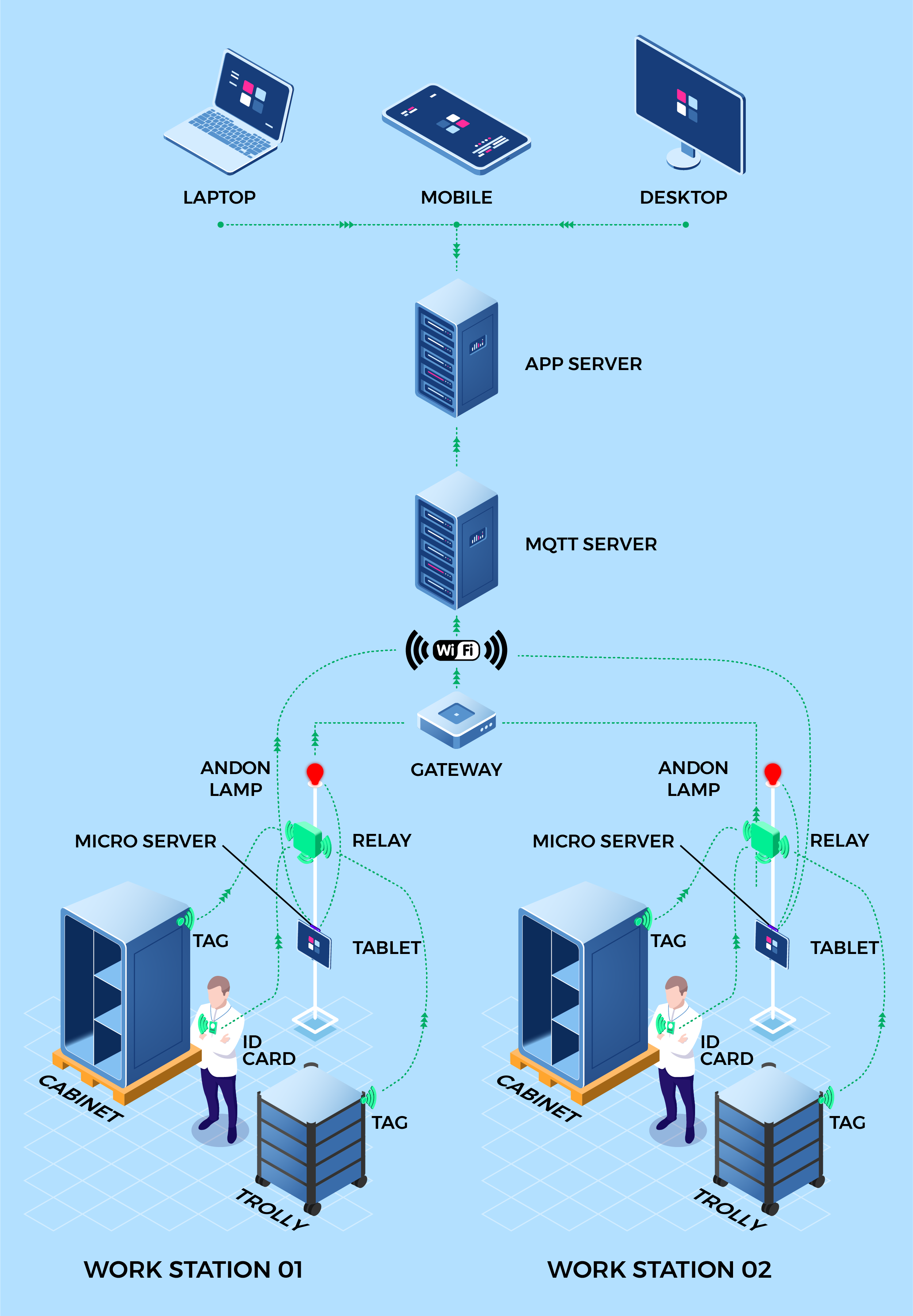

General IoT Architecture for Production Line

- BLE Tags are used on Pallets, Vehicles and Assets send singles of their location

- BLE ID cards are used to allocate human resources to operations and for visitors

- Zone Mapping is done using BLE Relays which also receive Signals from Tags and ID cards and transmit to Gateway Devices

- Gateways are devices which receive signals from Relays over BLE and Transmit to IoT server over WiFi

- IoT processes that data and gives it to the Application server where the business logic is applied and send to a web portal for display

- The display is done using Mobile Devices, laptops, tablets and TV screens

Business Value of Implementing IoT Based Processes

- Real-time Tracking of Process parameters and Critical Operations

- Asset, People and Vehicle Tracking

- Reduced TAKT for all operations thereby greater capacity and higher revenue growth

- Hyper Decision making looking and live dashboards

- Data Analytics

- Better Control over Production Processes

- Asset Mapping and location tracking at finger tips – smooth audits

- Predictable delivery of products

- Customer delight