Cold Storage Warehouse Management using RTLS (revised)

Cold Storage Warehouse Management Solution

USING RTLS (REAL TIME LOCATION SYSTEMS)

The Cold Storage Monitoring System implements sensor-based IoT technology to provide remote tracking and monitoring as well as early warning notifications and updates to prevent critical conditions. It helps provide better visibility and transparency across the entire value chain.

Features of Cold Storage Warehouse Management System

Realtime Tracking

Using RTLS technology the location of each asset tag can be tracked in real time. The location of these tags are traceable so that the path of movement is stored. These tags are attached to pallets and the equipment. The current locations are visible on the dashboard and is also possible to search for the pallet/equipment using ids.

Notification & Alerts

The asset tag on the pallets help track the location and if the pallets leave their designated areas it would trigger alerts and send notifications on the dashboard

Temperature & Pressure Monitoring

There is real-time tracking of the temperature & humidity levels in the Warehouse allowing remotely monitor and control the temperature to ensure that it is kept with in the control values.

SOS button

Employee tag will allow the employee to send out an SOS signal in case of any danger.

Inventory Management

When the produce/products get As soon as the pallet enters the warehouse and gets marked as inward, inventory gets updated automatically with out the need for any human intervention. Like wise when the pallets are taken out of the warehouse they get marked outward in the inventory.

Benefits of Cold Storage Warehouse Management System

SMART PALLET TRACKING

Using QuicSolv’s ISAE Framework built over Bluetooth Mesh tags and recan talk to each other and update the central server on its current location in real-time. A built-in accelerometer sensor will automatically update the system of its movement from the stored location.

EQUIPMENT TRACKING

The utilization sensor on equipment tags will keep a record of the amount of time the equipment is used, thereby helping make optimization decisions..

SMART NAVIGATION

The trackers insided the warehouse detect movement using movement sensors and lights are controlled by the trackers. Using the mobile app, once the item number or product name is entered, the app instantly able to find the location of the product. Real-Time Location – This technology could be used to not only find a product but also find the equipment.

Safety & Security

The employee entering the Warehouse would be provided with a Bluetooth tag will help keep a track on the time spent inside the warehouse and location in case of an accident as well as can act like an access control. In case of any incidents the employees can use SOS buttons to alert authorities of any emergencies.

ENERGY EFFICIENT

The data obtained from the temperature and humidity sensors is used to control the cooling systems to maintain the appropriate temperature within the warehouse. Additionally ML algorithm check to understand the patterns of dips in temperature and make adjustments to efficiently conserve energy.

Cold Storage Warehouse Management System

An easy to implement IoT based solution for the most demanding cold storage warehouses and help efficiently manage the storage, shipping, and distribution of products that need temperature-controlled environments

TALK TO US TO KNOW MORE ABOUT IT

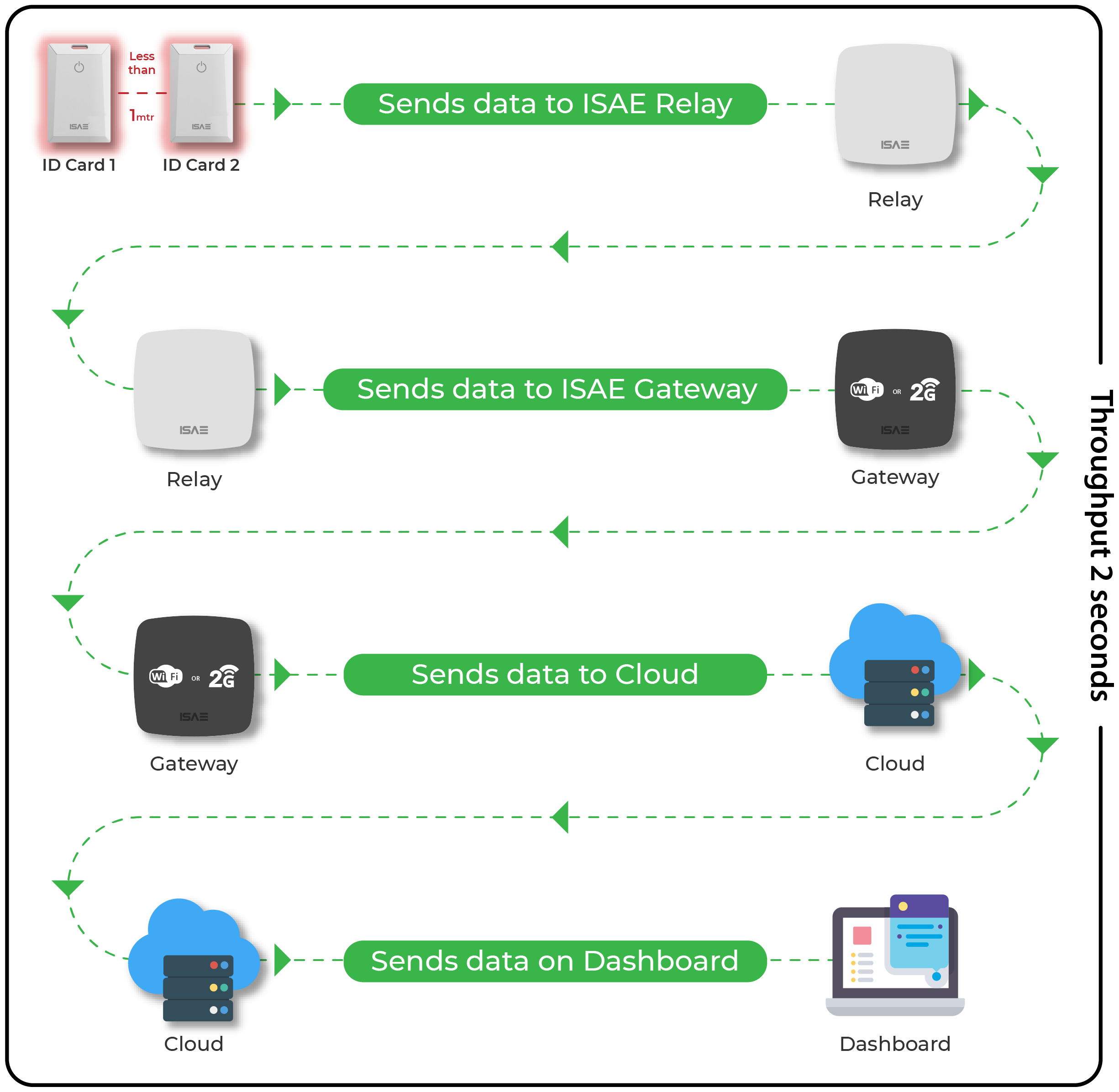

How does it work?

The solution is a BLE (Bluetooth Low Energy) based technology. The solution involves the deployment of the ISaE Gateways on the various security checkpoints. The Genio tags gives an identifier which is associated with the either a pallet or an equipment or employee in a process called provisioning. These Tags communicate continuously to the Gateways. The Gateways are connected to the ISaE cloud-based Command Center which records the position of the tags viz the pallet, equipment or employee. The track of each pallet position is kept along the date and time is stored in a database and maintained as a record for all future purposes. Additionally, temperature sensor and humidity sensors transmit the values continuously to gateways and these are send to the central ISAE server where it is processed to check if they are going beyond their control ranges. The alerts are generated if the control conditions are getting violated.