Dynamic Production Planning and Control

IoT based solution for Dynamic Production Planning

Change the way manufacturing processes are planned

Engage your plant in a more proactive manner with live monitoring and control

In a production environment, there are many dependencies that can disrupt the entire process resulting in a need to control these factors!!

Unpredictable Manpower

The production process is still dependent on manpower and unpredictability in terms of absences, late reporting leading to production plans getting disrupted and productivity getting impacted.

Dynamic Replanning

Delay Losses

DYNAMIC PRODUCTION PLANNING

An easy system to implement with a promise of many fold payoffs. Automatically be notified of absences, hands-off monitoring and

accuracy of data,

effective invoicing from vendors and lesser need for

manual audit, improving the effectiveness of production

planning

TALK TO US TO KNOW MORE ABOUT IT

KEY FEATURES

Low Maintenance

The tracking tags used have very low power requirements, therefore, have very low maintenance needed

Legacy Integration

Easily integrates with already existing legacy systems like SAP or any other ERP or Production Planning System. This kind of integration can help open up visibility into various aspects of human resource planning.

AI-based predictive planning

Additionally, use AI-based algorithms to start predicting manpower planning based on patterns to create buffers and manage productivity in non-linear and non-mechanical patterns.

Vendor & Contractor Management

Automatic attendance of contractors can be taken and hence can lead to better management of the contractors and takes care of a lot of aspects like invoice errors and discrepancies thereby leading to better vendor management.

Web based Dashboard

A web based remote dashboard allows one to remotely track the assets and locate the current location. This will help one locate them from anywhere

KEY BENEFITS

Lower Loss

The system ensures that there is better manpower planning happening around the production process.

Visibility

With the ability to track the assets – comes visibility organization-wide – the assets leave a trace at different points within the company premises as well as when it leaves the premise to be shipped to the vendor’s stock point or to the customer’s house.

BETTER OPERATIONAL EFFICIENCY

Upgrade your processes by adding automation to business flows and thereby removing steps delaying the process as well as those with manual intervention.

Customer Satisfaction

Clarity of the status of Customer Orders due to better visibility of the readiness of a shipment results in setting up the right expectations with the customers and thereby naturally a better Customer Satisfaction

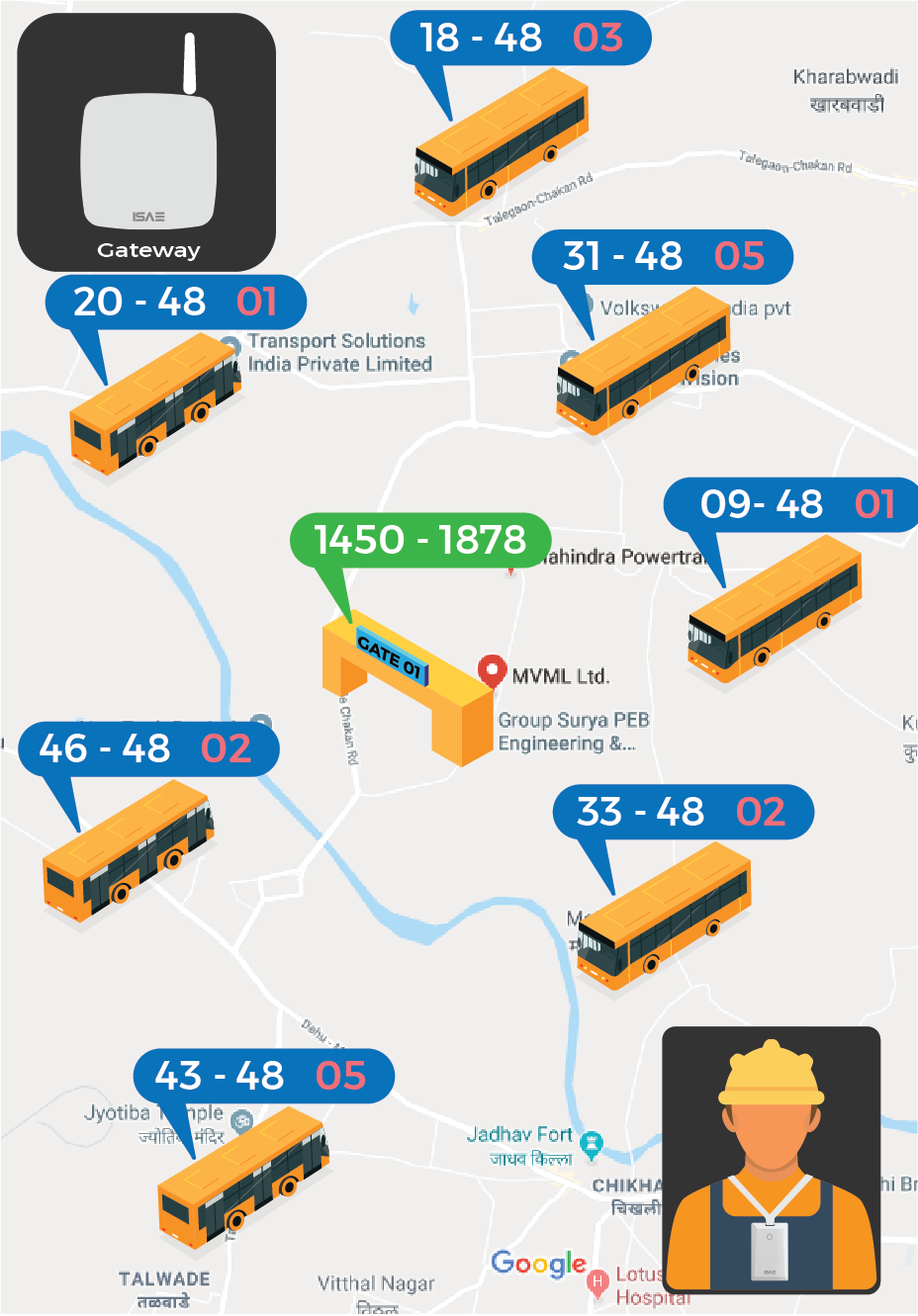

How does Dynamic Production Planning work?

Dynamic Production Planning needs that the employees to be provided with smart id cards. The buses that the employees travel from their homes to the office are installed with GPS-based smart gateways. As soon as the employees enter the bus, the attendance of the employee is marked. If the employee does not enter the designated bus and at the designated pickup point the HR and immediate manager are notified and marked in the system as an absence. This absence updates the staffing ratio which then is sent as an update to the Production Manager and also updates the production plan accordingly based on the new capabilities available.

Resources

I am raw html block.

Click edit button to change this html